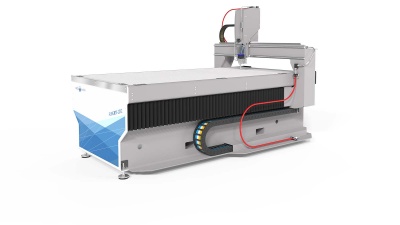

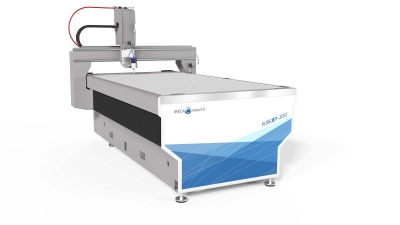

PUREJET

Water jet machine designed to simplify cutting of smooth or light material

- Description

- Technical datas

- Fields of activity

Water jet machine to simplify cutting of smooth or light material designed for industrial use

Entirely customizable and available in various sizes, PUREJET range is perfect for many materials :

- Rubber and derivatives

- Foams of all densities

- Leather and similar

- Low-thickness plastics and derivatives

- Rock wool, glass wool, plasterboard, etc.

- Cork and thin natural wood (marquetry, etc.)

- Solid or corrugated paper and cardboard, composites NOMEX® type or similar

- Woven or non-woven canvas, tarpaulins, etc.

- Pre-impregnated fabrics and mats of glass or carbon for the production of composite parts

STRENGHTS

Cuztomizable equipment

- 3 differents sizes

- Single or multi-heads

- Visible laser

- Additionnal modules for environment and operator protection

4136 bars HP Pumps created for this range

- Oil/water intensifier for 4000 bar continuous pressure with low maintenance cost

- 10HP version available in 230V single phase power supply

Optimized space

- Compact format

- Positionning stops

- HP flexibles hoses

Latest generation digital control

- 21 inches vertical touch screen on mobile control desk

- Modern and user-friendly HMI

- Programming up to 4 programs in cascading sequence

TECHNICAL DESCRIPTION

- Structure : Monobloc structure in machinewelded steel and moving gantry in machine-welded aluminium.

- Guidance : Grinded rails and preloaded ball bearings with NRII corrosion protection.

- Transmission : Transmissions by coated helical rack and pinion on X and Y axes and by ball screw on Z axis.

- Motorisation BRUSHLESS motors with absolute encoders on all axes.

DIMENSIONS

| PUREJET 1012 | PUREJET 2012 | PUREJET 4020 | |

| X axis travel in mm | 1050 | 2050 | 4050 |

| Y axis travel in mm | 1220 | 1220 | 2050 |

| Z axis travel in mm | 150 | 150 | 220 |

| Maximum material width on table | 1240 | 1240 | 2070 |

| Length in mm (pumps not included) | 1800 | 2850 | 5220 |

| Width in mm | 1995 | 1995 | 2950 |

| Height in mm | 1740 | 1740 | 2495 |

| Average weight in kg | 1000 | 1400 | 3750 |

HP PUMPS 4136 BARS

| MHP 1040 | MHP 2040 | MHP 3040 | |

| Power HP/ kW | 10 HP / 7,5 kW | 20 HP / 15 kW | 30 HP / 22 kW |

| Maximum pressure | 4136 bars | 4136 bars | 4136 bars |

| Advised working pressure | 3800 bars | 3800 bars | 3800 bars |

| Maximum flow litres/minutes at pressure 3800 bars | 0,86 l/min | 1,62 l/min | 2,45 l/min |

| Pump capacity at 3800 bars: max. number of heads/max. nozzle diameter |

2 / 0,10 mm or 1 / 0,15 mm |

2 / 0,15 mm | 3 / 0,15 mm |

| Pump capacity at 3000 bars: max. number of heads/max. nozzle diameter |

1 / 0.18 mm or 2 /0.12 mm |

1 / 0,25 mm or 2 / 0,18 mm |

1 / 0,33 mm or 2 / 0,22 mm or 3 / 0,18 mm |

| 230V single phase power supply a nd required Amperes per phase (pump only) |

38 A | non available | non available |

| 400V three-phase power supply and required Amperes per phase (machine + pump) |

3 x 16 A | 3 x 29 A | 3 x 45 A |

| Pump module overall dimensions (L x W x H) in mm | 1600 x 800 x 1300 | 1600 x 800 x 1300 | 1600 x 800 x 1300 |

Naujų medžiagų apdirbimas aviacijos ir kosmoso pramonėje: MÉCANUMÉRIC, kompetencija inovacijų labui

Privalumai, iššūkiai ir mechaninio apdirbimo problemos: kompozicinės medžiagos turi didelių privalumų aeronautikos sektoriuje, tačiau kokius iššūkius reikia įveikti, norint jomis pasinaudoti?