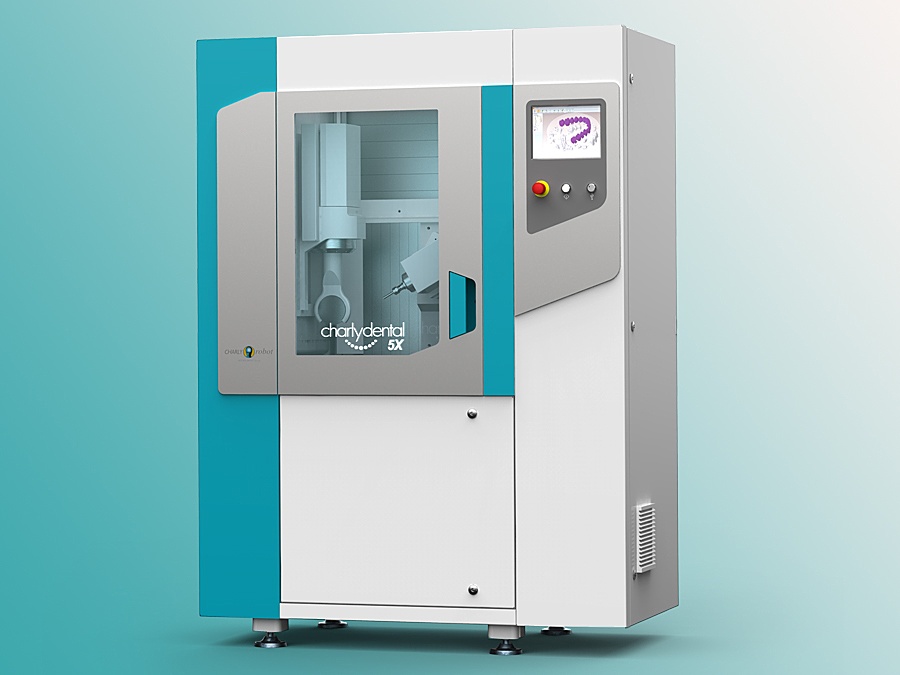

CHARLYDENTAL CD 50

Premium CN milling machine with 5 simultaneous axes for the metal (chromium-cobalt and titanium)

- Description

- Technical datas

- Fields of activity

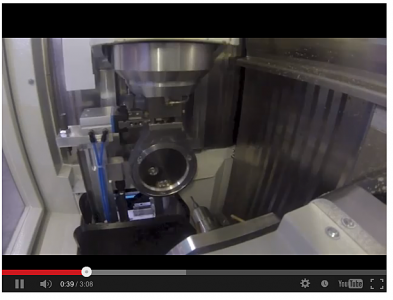

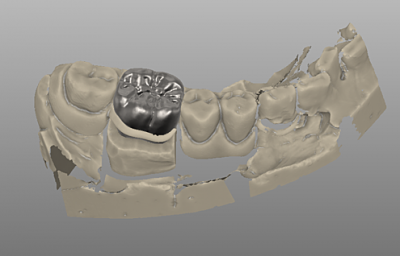

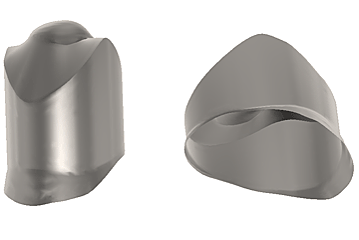

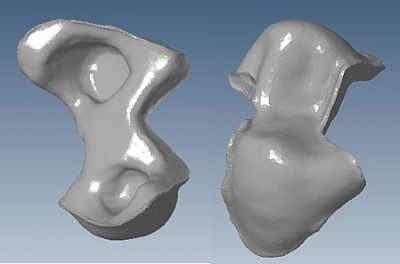

A true concentrate of performance, the milling machine is designed to allow intensive machining of Chrome-Cobalt and Titanium, in 5 continuous axes, as well for the production of frameworks for fixed prostheses, as implant bars or personalized abutments for implantology.

The power of the 4 kW spindle greatly reduces the roughing times (CrCo), the speed of 50,000 rpm allows the use of tools up to 0.5 mm in diameter for very small details. The equipment incorporates industrial technology known as "UGV" (High Speed Machining).

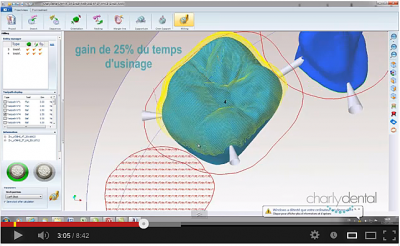

CHARLYROBOT further confirms its winning partnership by partnering with WorkNCdental technology for the CAM part (charlydentalCAM 5X). The new optional “implant module” allows the production of numerous implant parts with a wide choice of connectors.

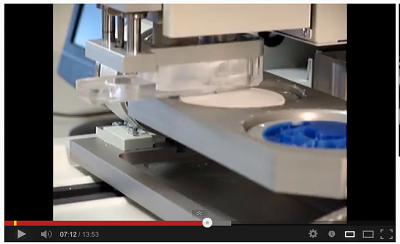

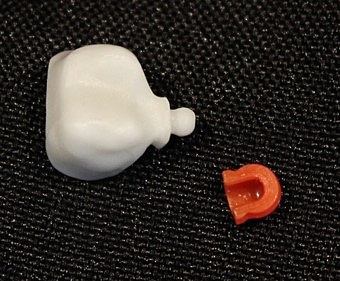

Its 15-position automatic tool changer, its 4-position disc magazine, soluble oil lubrication with abundant jet, by water or dry (suction), allows it to also work pre-sintered zirconia, resins for temporary , lithium disilicate and even burnable waxes (chassis for mobile prostheses). Its disc loader is optional.

STRENGHT

- Monobloc steel frame with moving parts in aluminum casting

- High quality kinematics by rectified rails and ball screws.

- 5 continuous digital axes digital control and optimized control for fine machining and perfect finishes.

- Ease of use that makes the reputation of the CHARLYDENTAL brand.

Machine optimized for machining the following materials:

- Chrome-Cobalt alloy

- Titanium

- Zirconium oxide

- Ceramics

- PMMA / WAX

- PEEK

TECHNICAL CHARACTERISTICS :

- 5 simultaneous axes machining,

- Brushless servomotors,

- 10 '' touch screen,

- High precision 4Kw electrospindle - 50,000 rpm,

- Work dry or with tool coolant,

- Tool magazine with 10 tools with 1 µm precision tool length sensor and replacement tool management.

DIMENSIONS

| CD 50 | |

| Lenght | 1400 |

| Width | 790 |

| Height | 1950 |

| Weight | 1150 |