MECABOND

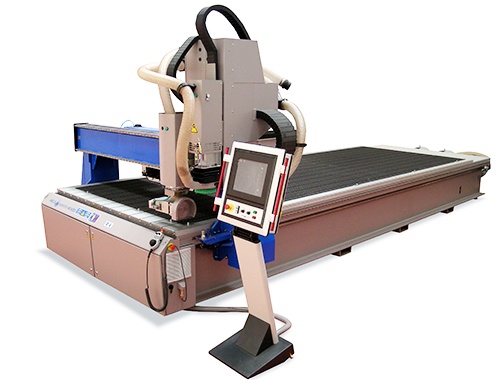

High productivity 4 axis multi head milling CNC machine optimized for sign applications and frontages in the building area.

- Description

- Technical datas

- Fields of activity

MULTI-SPINDLE CNC 4-AXIS MILLING MACHINE

High productivity system for the rapid cutting of sheet materials in the building (facades), sign or fitting out of commercial vehicles (refrigerated trucks, etc.) sectors.

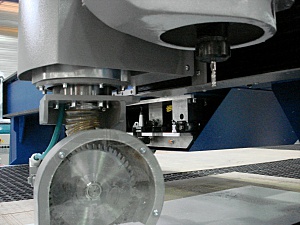

4-axis CNC milling machine that can be equipped with a high-power vertical electrospindle and a horizontal electrospindle that can be rotated 360 degrees.

TECHNOLOGIES

- Kinematic assembly with fixed table and mobile gantry.

- Monobloc frame in mechanically welded steel.

- Mobile gantry in mechanically welded steel.

- Vacuum tray in aluminum profile.

- Support of the plates by the vacuum generated either by lateral channel turbines or by vacuum pumps with nozzles.

- Automatic selection of zones by solenoid valves. Timing stops automatically retractable plates.

- Motorization by AC Brushless servomotors on the 6 axes (X1-X2-Y-Z1-Z2-C).

- Transmission by high precision rack and pinion systems for X and Y axes, ball screw on Z axes, gearbox without play on C axis

- Guides by rectified rails and pre-loaded pads with ball circulation.

- MECANUMERIC CN7000 Digital Control with 15 inch touch screen, integrated hard drive, Ethernet port, USB port. Import of files in ISO code.

- Wide choice of horizontal and vertical electrospindles.

Some of the materials that can be used (depending on the electrospindle and the tool chosen):

- Rigid plate plastics (PMMA-PC-PS-PVC-ABS ..)

- Expanded plastics and cellular sheets

- Rigid foam (PU- PS-…)

- Semi-rigid foams (KAPA line®,…)

- Composite materials for the building industry: Alucobond®, Dibond®, Reynobond®, ..

- Composite materials for industry (polyester resin filled with glass fiber, carbon fiber, etc.)

- Wood and wood products

- Polyester resins

- Light alloys aluminum base or copper base

SOME OF THE POSSIBLE OPTIONS

- Chip extraction by a wide choice of industrial suction groups.

- Different vacuum plates.

- Tool magazine on board (capacity 6 cones) with tool length sensor.

- Tool lubrication system / Tool / material cooling system

- Suction zones with automatic selection controlled by numerical control.

- SIEMENS SINUMERIK® 840 Di digital control and SIEMENS servomotors.

- Retractable timing stops (5 lateral stops and 3 frontal stops for MB60xx or 3 and 2 for MB42xx).

- Automatic dispenser for VILMILL® support film.

- Remote electronic crank.

- Safety zone around machine controlled by radar or light curtains.

- Automatic unloading loading system by spreader or interchangeable tables.

TECHNICAL CARACTERISTICS :

- Maximum speed: 1000 mm / sec

- Acceleration: 1 ms²

- Repeatability: +/- 0.05 mm

- Resolution: 0.001 mm

DIMENSIONS

| MB 6020 | |

| X stroke | 6050 |

| Y stroke | 2070 |

| Z-axis travel in mm (maxi/working travel) | 340/100 |

[TEMOIGNAGE] 3DScube - Communication visuelle

3DS produit tous types de supports de communication visuelle dans une grande variété de matériaux : bois, plastiques, aluminium...

RD SIGNS (Reklaminių ženklų gamyba)

RD SIGNS gamina lauko reklamos priemones daugeliui klientų Europoje.

Naujų medžiagų apdirbimas aviacijos ir kosmoso pramonėje: MÉCANUMÉRIC, kompetencija inovacijų labui

Privalumai, iššūkiai ir mechaninio apdirbimo problemos: kompozicinės medžiagos turi didelių privalumų aeronautikos sektoriuje, tačiau kokius iššūkius reikia įveikti, norint jomis pasinaudoti?

![[TEMOIGNAGE] 3DScube - Communication visuelle](/medias/articles/vignettes/logo3dscube_1_1_4.jpg)