OTHER SECTORS

MECANUMERIC has a long experience in the manufacture of CNC machines and offers state-of-the-art solutions for CNC waterjet THP cutting and milling of all types of parts in various materials.

Manufacturer of industrial equipment, MECANUMERIC has designed ranges of 3, 4 and 5 axis digital milling machines as well as CNC waterjet machines for numerous applications such as the manufacture of foam for suitcases, the cutting of horseshoes or masks, the reproduction of statues, the production of boxes and electroerosion electrodes.

CNC milling machines for cutting foam for cases

Many products are marketed in cases with a protective foam. The equipment in the case is thus protected by the foam during transport. The machining of the particular materials that are the more or less dense foams composing this type of case is greatly facilitated by the use of a 3-axis CNC milling machine.

The Charly4U - Charly2U, MECAEASY or MECAPRO models are suitable for the manufacture of the foams to be inserted in the cases. Indeed, these digital milling machines can mill in 2D or 3D (MECAEASY) and have an excellent price/performance ratio (Charly4U - Charly2U, MECAPRO) appreciated for mass production.

Industrial tools for cutting horseshoes and masks

Cutting by 3-axis CNC digital milling allows us to obtain a perfect finish for the manufacture of horseshoes used in the farriery. Even though horses' hooves are strong, a horseshoe can injure them. The manufacture of horseshoes must therefore be meticulous.

The production of masks in series or for one-off models can be carried out using a 3-axis CNC milling machine from a digital mould. The CNC control allows for both repeatability and one-off production with the same degree of precision and finish.

In the range of MECANUMERIC CNC machines, the Charly4U - Charly2U, MECAEASY and MECAPRO models are high-performance industrial equipment adapted to the manufacture of masks and horseshoes for the farriery.

MECANUMERIC : manufacturer of CNC machines for statue reproduction

The manufacture of statue replicas requires the use of CNC machines allowing precision machining whatever the shape, material and size of the parts to be reproduced. A 5-axis digital milling machine for 3D machining is the industrial equipment dedicated to this type of work.

The numerical control allows to work from a moulding. The impression can be taken by hand. It can also be done digitally. This method limits the risk of damaging the initial works and allows them to be reproduced and replicated in sizes different from the original (larger or smaller).

Statues can be reproduced in many materials such as plastics, resins, foams, wood, aluminium, brass and various alloys.

The NORMAPROFIL WINNER series allows the milling of all these types of materials. It can also be used to machine large parts. The models can be thermoformed, rotomoulded or injected.

Industrial equipment for the production of boxes

Boxes, made of wood or other materials, have many uses. They can be used for transporting and storing tools, wines and spirits, jewellery, fine arts or even timepieces.

The production of boxes can be done in series in a simple and efficient way thanks to the use of a 3-axis CNC milling machine. Combining performance and productivity, the MECAEASY, MECAPRO and MECAPLUS models offer a high level of precision while allowing a high level of repeatability.

Boxes manufactured for the luxury goods, cosmetics or watchmaking industries require increased precision and high quality finishes. MECANUMERIC's 3-axis digital milling machines deploy technology that meets the production quality requirements while keeping the budget under control for this type of application.

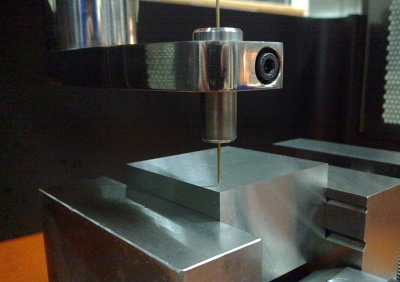

3-axis digital milling machines for the production of EDM electrodes

EDM is a machining process for working particularly hard materials and in very small formats. The machining of the workpieces removes material by means of electrical discharges. This technique requires a great deal of know-how and extreme precision.

Electrical discharge machining (EDM) is used for the production of mass-produced parts. It allows engraving but also cutting. The manufacture of EDM electrodes is possible thanks to 3-axis digital milling machines.

A 3-axis CNC milling machine allows cutting and milling on the surface of the part to be machined as well as in depth (sinker EDM) to make moulds or deep engravings. Fine and precise 2D or 3D machining can thus be carried out in various materials such as aluminium, brass or stainless steel for example.