CHARLYDENTAL CD04-S

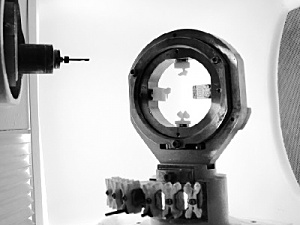

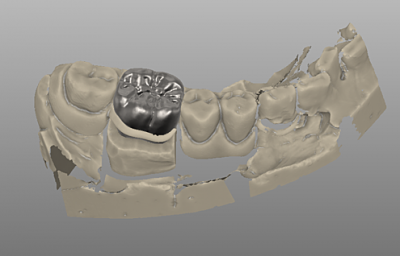

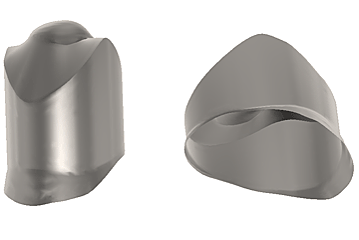

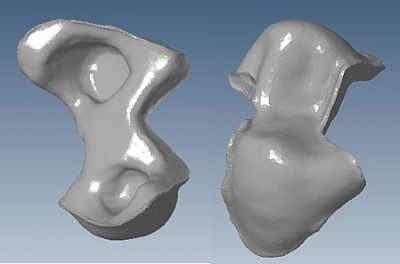

Milling/grinding machines for dental prostheses available in versions 4 positioned axes, perfect for a simple and fast daily production of prostheses in soft materials and ceramics, with dry or lubricate tool.

- Description

- Technical datas

- Fields of activity

Thanks to their very compact dimensions and to the original choice of kinematics, they offer a maximum of flexibility for a minimum of space.

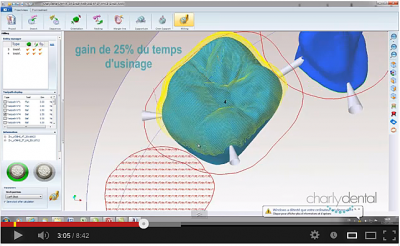

They are equipped with an open CAD/CAM system which can be used with the main scanners, CAD/CAM software and consumables used in the dental field.

Other highlights of this concentrate of innovation totally designed and manufactured in France :

• Power reserve by 500W – 60000 rpm spindle and brush-less servo-motors

• Flexibility and accuracy of milling/grinding with angulation of the rotary axes

• 4th axis : +/- 30°

• Accuracy by high quality kinematics, ball-screws, and rectified rails

• Simplicity of use thanks to the colour touch screen and its driving friendly software

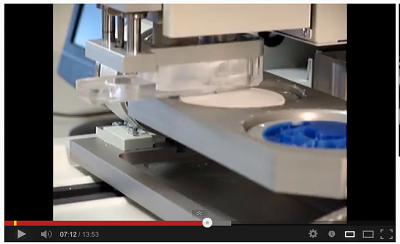

• High performance automatic monitoring of the tools and the brother-tools changes, wearing and tools breaking detections

TECHNICAL CHARACTERISTICS

- Brushless servo motors

- Spindle 500 W 60,000 rpm

- Automatic tool change (with 12 tools in the changer)

- Precision measurement of tool length

- Tool breakage detection

- Tool wear detection

- Integrated suction sensor

- Communication port: 1 USB and 1 ETHERNET

- Power supply: 230 VAC 50/60 Hz

DIMENSIONS

| CD04-S | |

| Lenght | 542 |

| Widht | 600 |

| Height | 736 |

| Weight | 90 |